QFN soldering machine

3 heating zones touch screen BGA reballing machine is a specialized equipment used in the electronics industry for repairing and reworking Ball Grid Array (BGA) components. BGA components are commonly used in electronic devices, and when they fail, they can be challenging to repair or replace. The BGA reballing machine is designed to make this process easier and more efficient.

Aprašymas

3 heating zones touch screen BGA reballing machine

The machine has three heating zones, which allows for precise control of the temperature during the reballing process.

The touch screen interface provides an easy-to-use interface for setting and monitoring the temperature, as well as for

selecting the appropriate programs for different types of BGAs. The machine is specifically designed for reballing, which

involves removing the existing solder balls and replacing them with new ones, ensuring that the BGA component is prop-

erly attached to the circuit board and functioning correctly.

Overall, the 3 heating zones touch screen BGA reballing machine is an essential tool for anyone who needs to repair and

rework BGA components in the electronics industry.

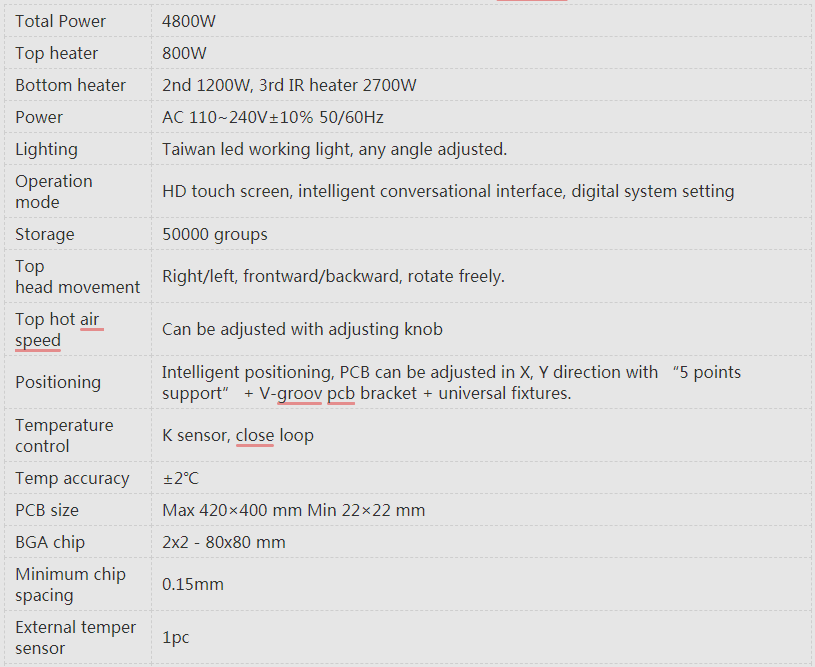

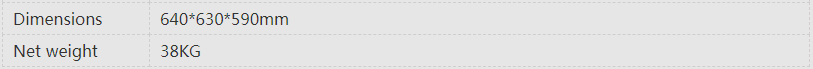

The product parameter of 3 heating zones touch screen BGA reballing machine

The product feature of 3 heating zones touch screen BGA reballing machine

3 independent control heaters

Here are some features of a 3 heating zones touch screen BGA reballing machine:

Touch screen control: The machine is equipped with a touch screen display that allows the user to

easily set and control various parameters such as temperature, heating zones, and timing.

3 heating zones: The machine has three heating zones, each of which can be independently contro-

lled and set to a different temperature. This allows for precise control of the heating process and h-

elps ensure a consistent and uniform reballing process.

Temperature control: The machine is equipped with advanced temperature control technology, allo-

wing the user to precisely set and maintain the temperature required for a successful reballing proc-

ess.

High-quality components: The machine is built with high-quality components and materials, ensuring

reliable and consistent performance over time.

Easy to use: The touch screen control interface is designed to be user-friendly and intuitive, making it

easy for users to set up and operate the machine, even if they have limited experience with reballing

machines.

Main parts explaination:

The product details of 3 heating zones touchscreen (3 Heating Zones Touch Screen Bga Reballing Machine)

A high-quality BGA rework station will have a well-designed hot air flow system that provides

consistent and uniform heating of the BGA component and the surrounding area. This is critic-

al to ensure a successful BGA rework process, as uneven heating can cause the solder to soften

too quickly or not enough, leading to damage to the component or the PCB. Some of the top fe-

atures to look for in a BGA rework station with regards to hot air flow include:

Adjustable flow rate: The ability to adjust the flow rate of the hot air can help ensure that the

component is heated evenly and that the temperature is controlled precisely.

(3 Heating Zones Touch Screen BGA Reballing Machine)

The vacuum pen is an important tool in the BGA rework process because it allows the user to handle the

BGA component without touching it with their hands, which can cause damage to the delicate solder balls

on the component. The vacuum pen also provides a stable and precise means of positioning the component

onto the PCB, which is critical to ensure a successful rework process.

(3 Heating Zones Touch Screen BGA Reballing Machine)

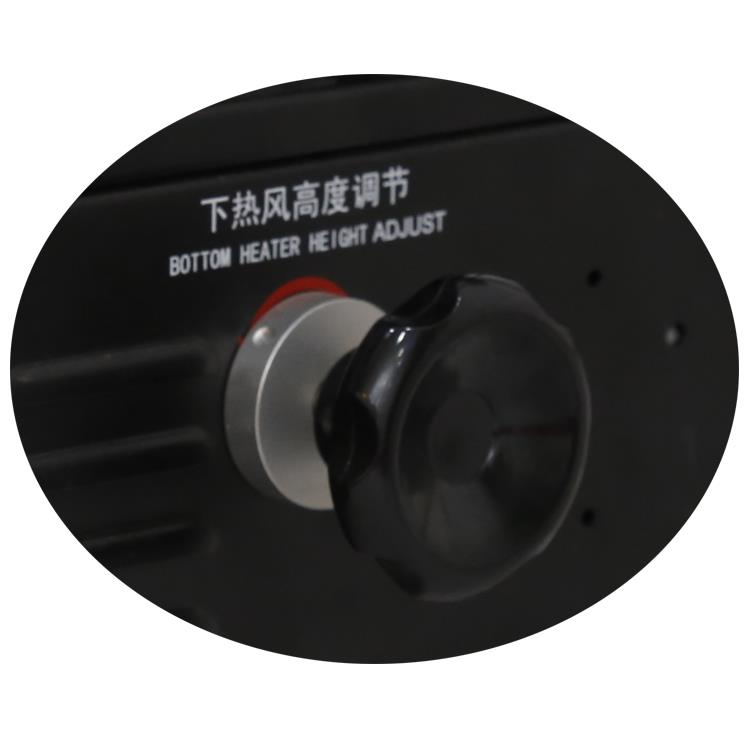

The height of the hot air nozzle on a BGA rework station can be adjusted to control the temperature and

flow of hot air that is used to heat the BGA (Ball Grid Array) component and the surrounding area on the

printed circuit board

(3 Heating Zones Touch Screen Bga Reballing Machine)

The touchscreen of a BGA rework machine is a user interface element that allows the operator to control

and monitor the rework process. It typically consists of a color display screen that is integrated into the m-

achine's control panel, and is used to display information such as temperature settings, process status, and

error messages. The touchscreen can be used to input commands and make adjustments to the machine's

parameters, such as temperature and hot air flow rate.

These customers are those who have bought our BGA rework machines, and most of them are

still looking forwarder to further cooperation for Automatic locking machine and Auto solder-

ing station etc.

The FAQ of 3 heating zones touch screen BGA reballing machine

3 Heating Zones Touch Screen Bga Reballing Machine

1. Q: Is this machine with hot air only?

A: NO, it has 2 hot air heaters, 1 infrared preheating zone.

2. Q: What is BGA?

A: Ball Grid Array, a kind of chip that widely used.

3. Q: Do I need adequate operator training before using BGA rework station?

A: The skill can be practiced, and itself is developing, you can use and study.

4. Q: Is a successful temperature profile perfect ?

A: The BGA rework profile is as important as the assembly reflow profile, and in most cases duplicates

it. Without it, you won't achieve a successful and repeatable BGA rework process.