IR6000 bga rework station

1. High success rate of repairing chips.

2. Simple and easy operation

3. Infrared heating. No damage to PCB and chip.

Aprašymas

IR6000 bga rework station

The IR6500 BGA rework machine can repair a wide range of BGA chips, including:

Graphics Processing Units (GPUs)

Central Processing Units (CPUs)

Memory chips such as DDR, DDR2, DDR3, DDR4

System-on-a-Chip (SoC) devices

Networking chips

Wireless communication chips

Power management chips

Audio chips

Microcontroller units (MCUs)

FPGA and CPLD chips

Note that the ability to repair a specific BGA chip depends on the design and size of the chip, as well as the

capabilities of the IR6500 BGA rework machine. It's always best to consult the manufacturer's specifications

and guidelines to determine the specific chips that can be repaired using the IR6500 BGA rework machine.

2.Product Features of Keyboard Game Consoles BGA Rework Machine

(1) Precise temperature control.

(2) The high success rate of repairing chips.

(3)Two infrared heating areas increase the temperature gradually.

(4)No damage to chip and PCB.

(5)CE certification guaranteed.

(6) Sound hint system: there are voice reminder 5s-10s before the completion of heating, to get the operator prepared.

(7) V-groove PCB works for rapid, convenient and accurate positioning, which can meet all kinds of PCB boards of positioning.

(8) V-groove PCB works for rapid, convenient and accurate positioning, which can meet all kinds of PCB boards of positioning.

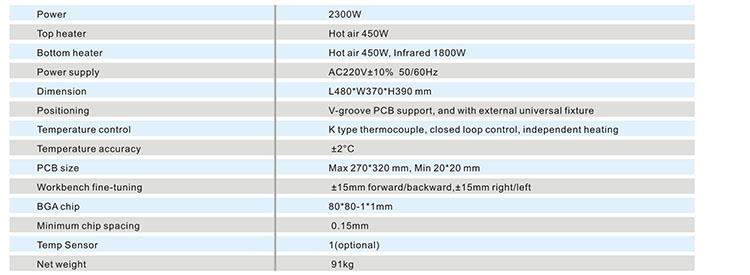

3.Specification of Keyboard Game Consoles BGA Rework Machine

4.Details of Keyboard Game Consoles BGA Rework Machine

1. Two infrared heating zones ;

2. Led headlamp;

3. Dashboard operating;

4. Limit bar.

5. Certificate of Keyboard Game Consoles BGA Rework Machine

6.Packing & Shipment of Keyboard Game Consoles BGA Rework Machine

The IR6500 BGA station is a device used in the repair of printed circuit boards. It's typically used in electronics

repair, particularly in the rework of Ball Grid Array (BGA) components. The IR6500 uses infrared heating techn-

ology to remove and replace BGAs in a precise and controlled manner.

Here are some common uses and applications of the IR6500 BGA station:

BGA Rework: The IR6500 can be used to remove and replace damaged or faulty BGAs on circuit boards. This is

accomplished by heating the BGA to a specific temperature and applying precise amounts of force to remove the

component from the board.

BGA Reballing: The IR6500 can be used to replace old or damaged BGA balls with new ones, improving the conn-

ection between the BGA and the circuit board.

BGA Testing: The IR6500 can be used to test the functionality of BGAs after rework or repair. This can help to ide-

ntify any issues that may need to be addressed before the board is put back into service.

BGA Prototyping: The IR6500 can be used in the development of new circuit board designs, allowing engineers to

quickly prototype and test BGAs without having to build a new circuit board each time.

The IR6500 BGA station is a valuable tool for electronics repair technicians, PCB designers, and engineers who nee-

d to repair or test circuit boards that contain BGAs. With its precise heating technology and controlled operation, the

IR6500 can help ensure that BGAs are reworked or replaced correctly and efficiently.